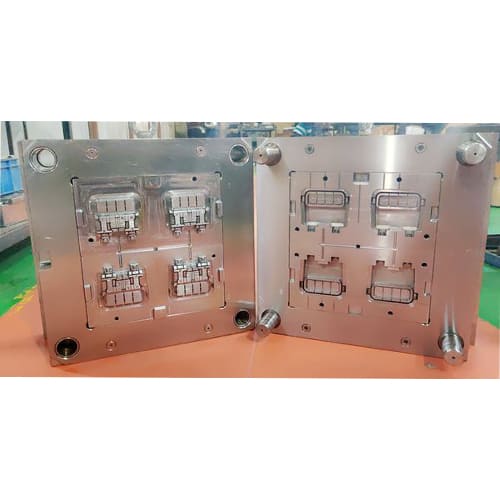

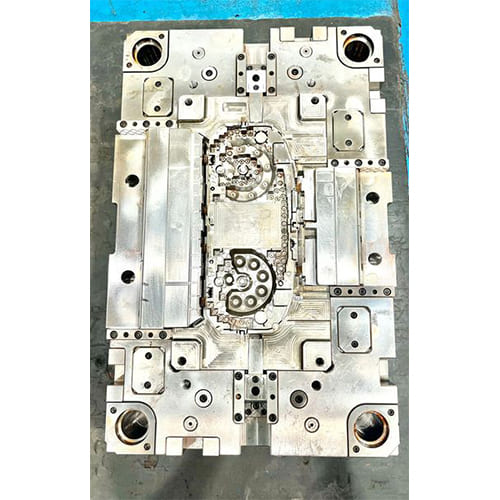

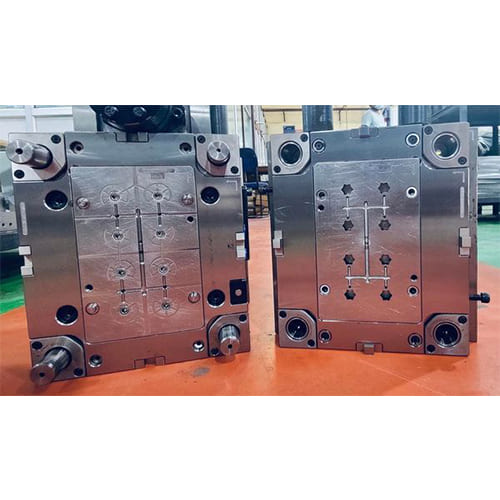

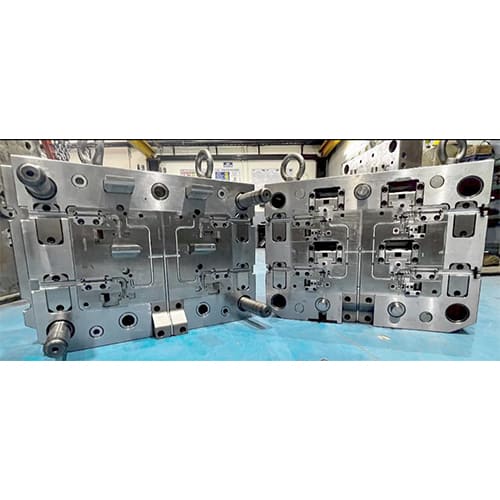

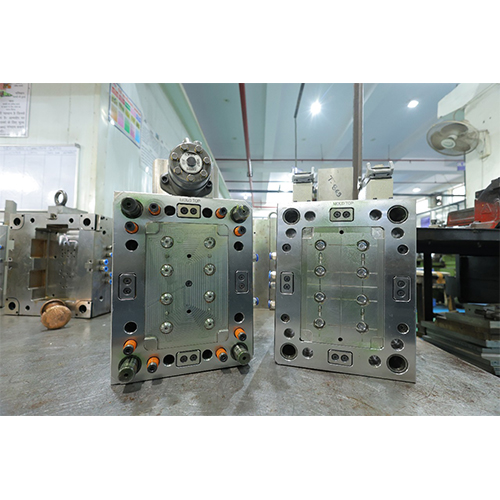

Injection Mould

Injection molding is a manufacturing process used to create parts by injecting molten material into a mold. This process is widely used for producing plastic parts, but it can also be applied to metals, glass, and other materials. The process is highly efficient and allows for high precision and repeatability, making it ideal for mass production.

Here’s a basic rundown of how it works:

1. Material Preparation: The raw material, usually in the form of pellets, is fed into a hopper.

2. Melting: The material is heated in a barrel until it becomes molten.

3. Injection: The molten material is then injected under high pressure into a mold cavity.

4. Cooling: The material cools and solidifies in the mold.

5. Ejection: Once cooled, the mold opens, and the finished part is ejected.