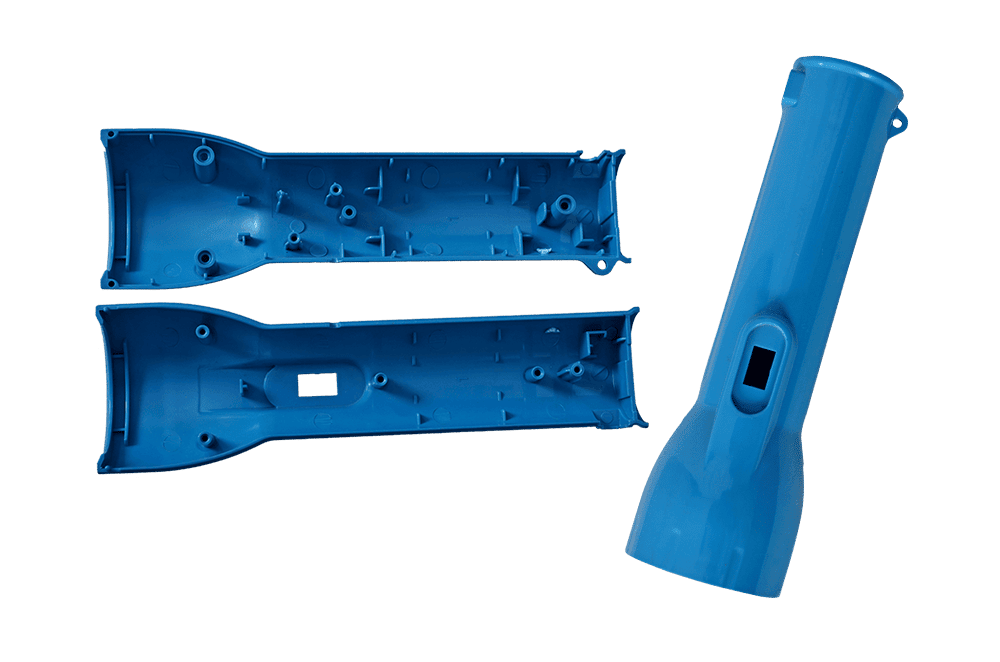

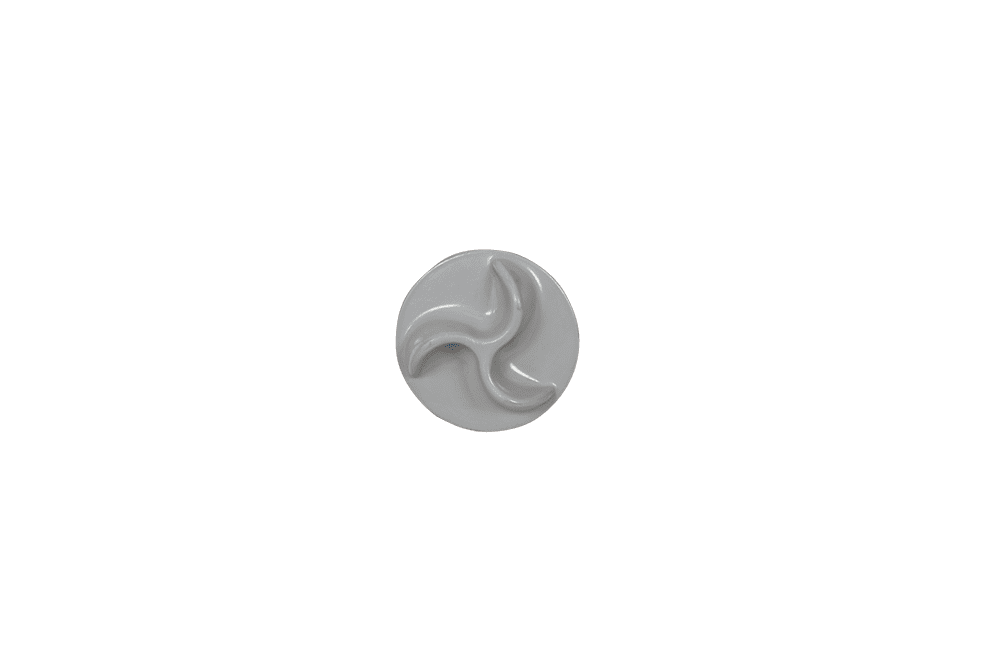

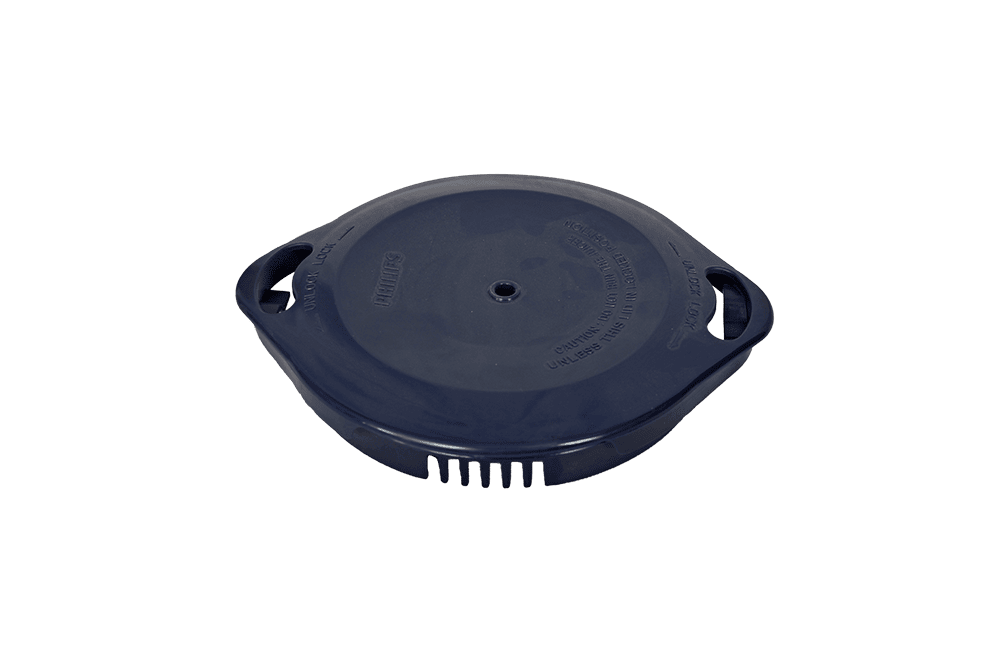

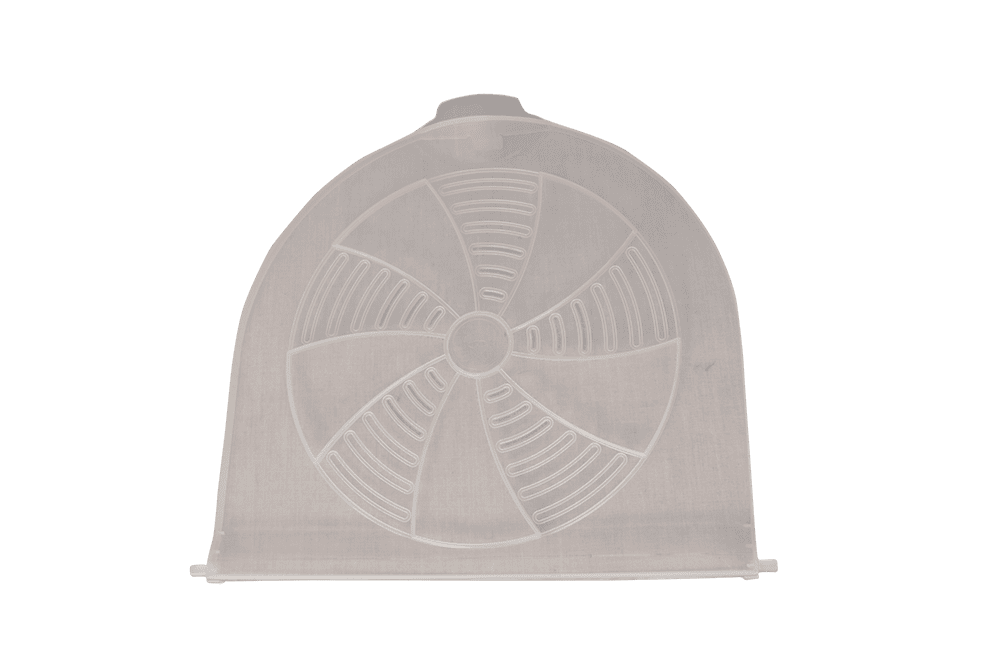

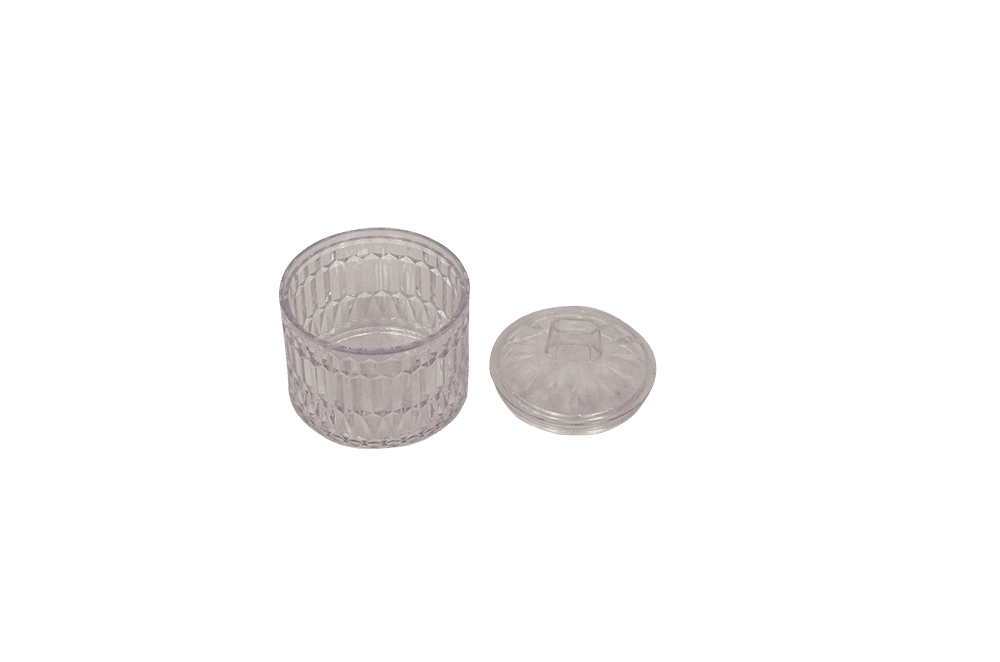

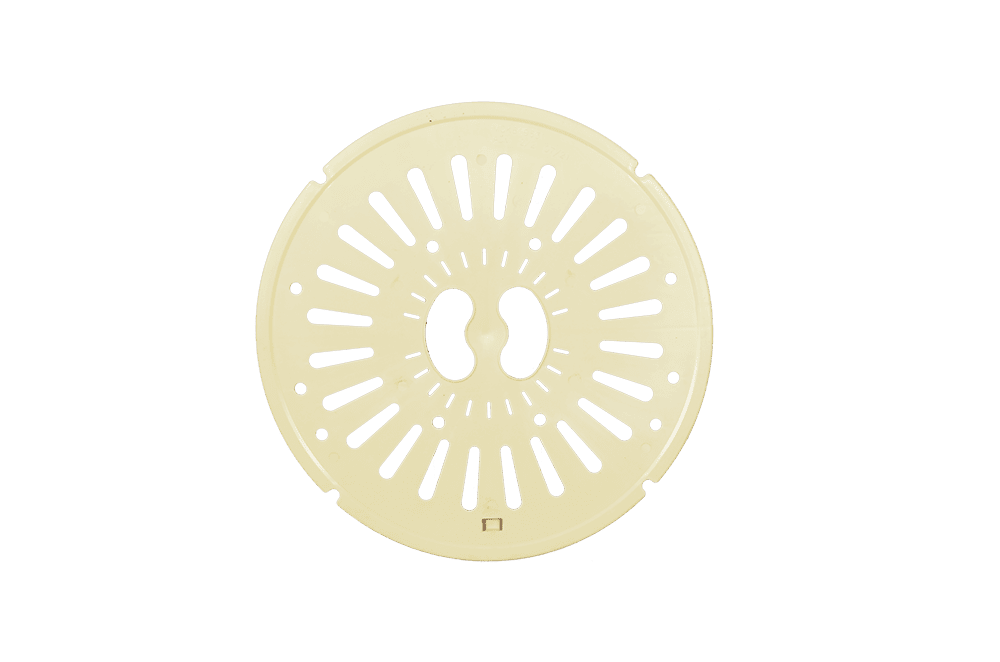

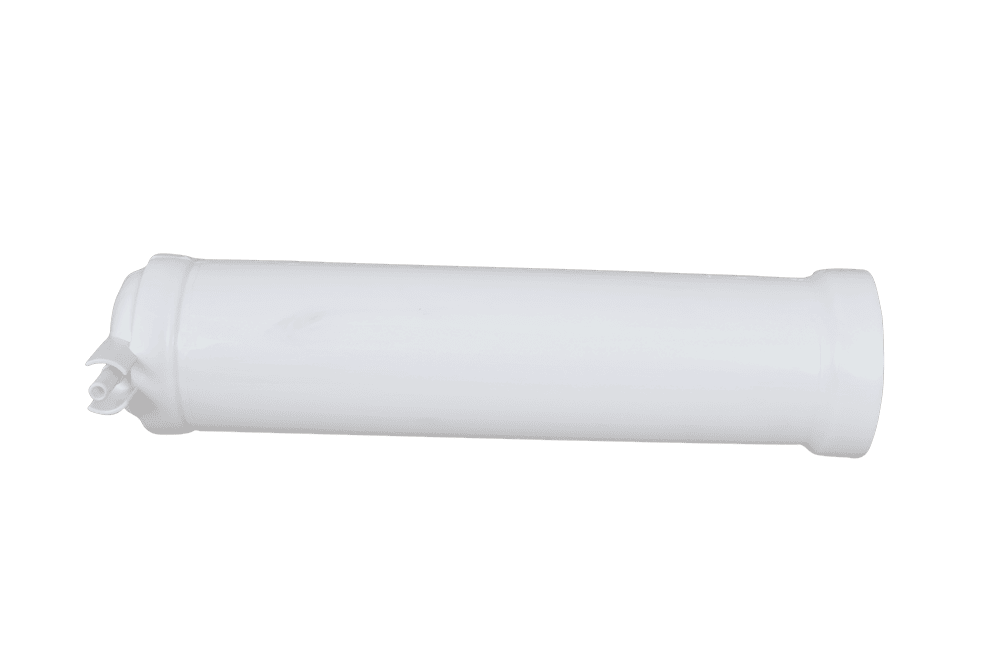

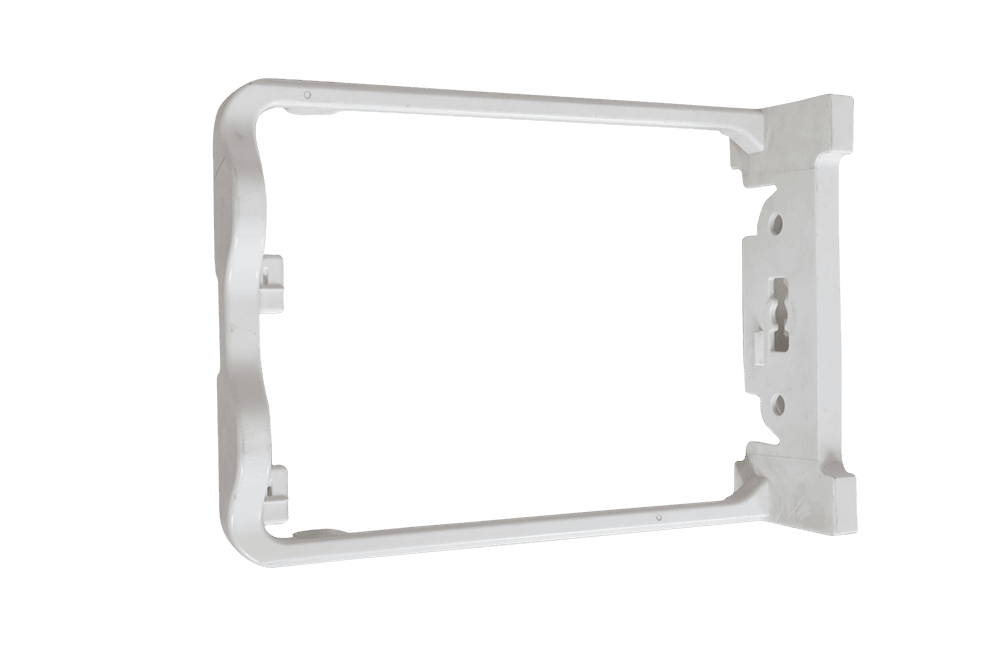

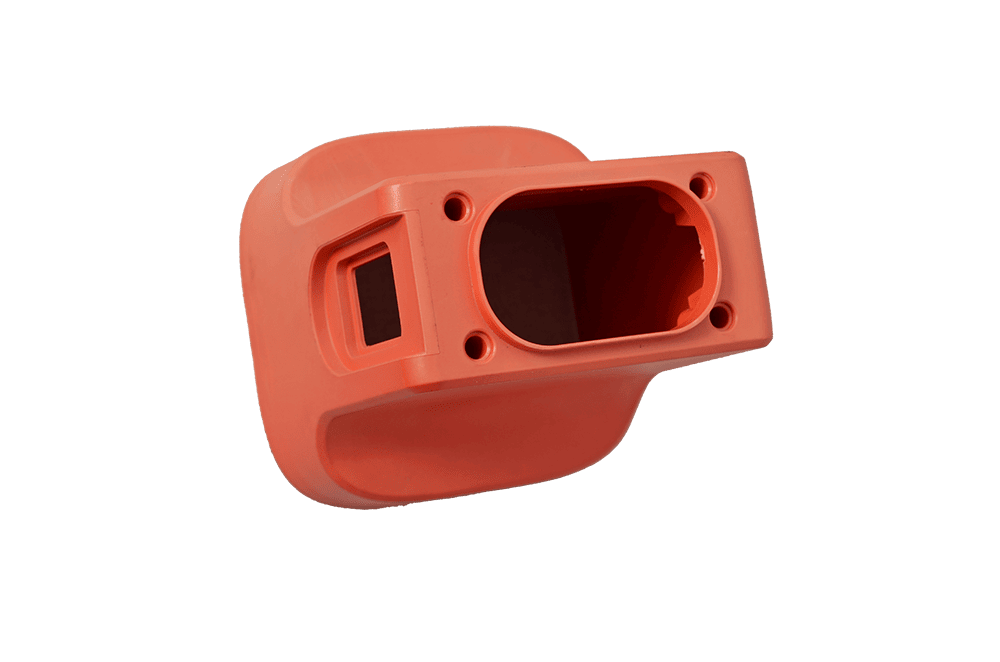

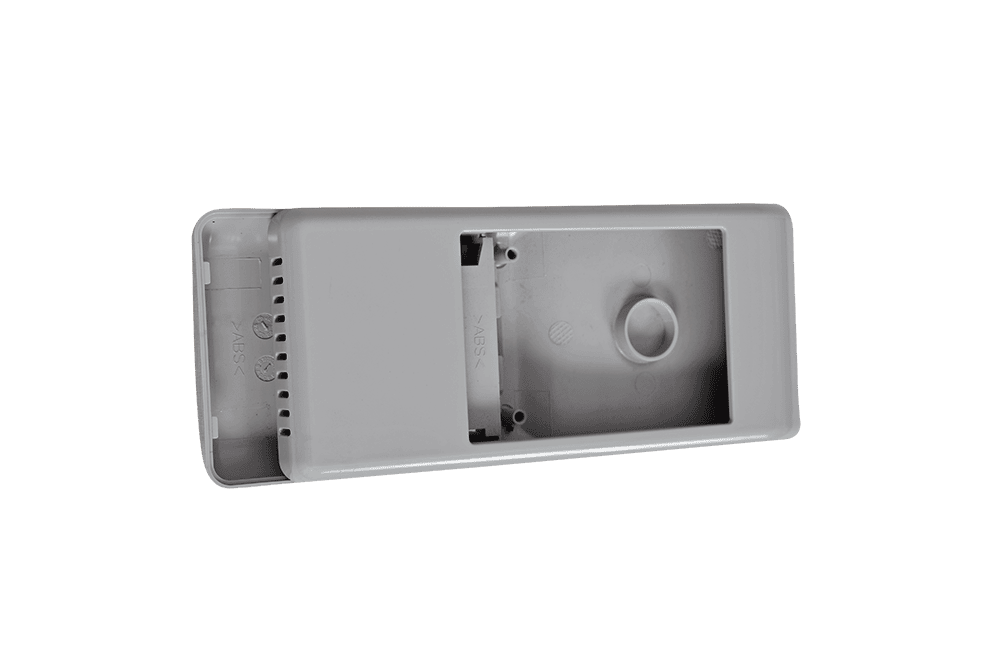

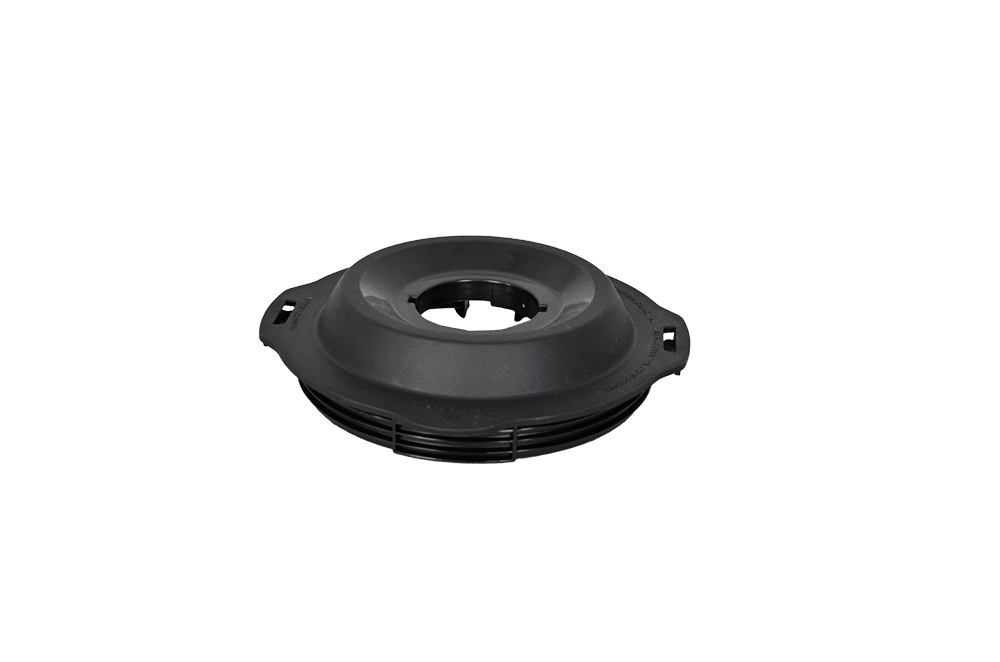

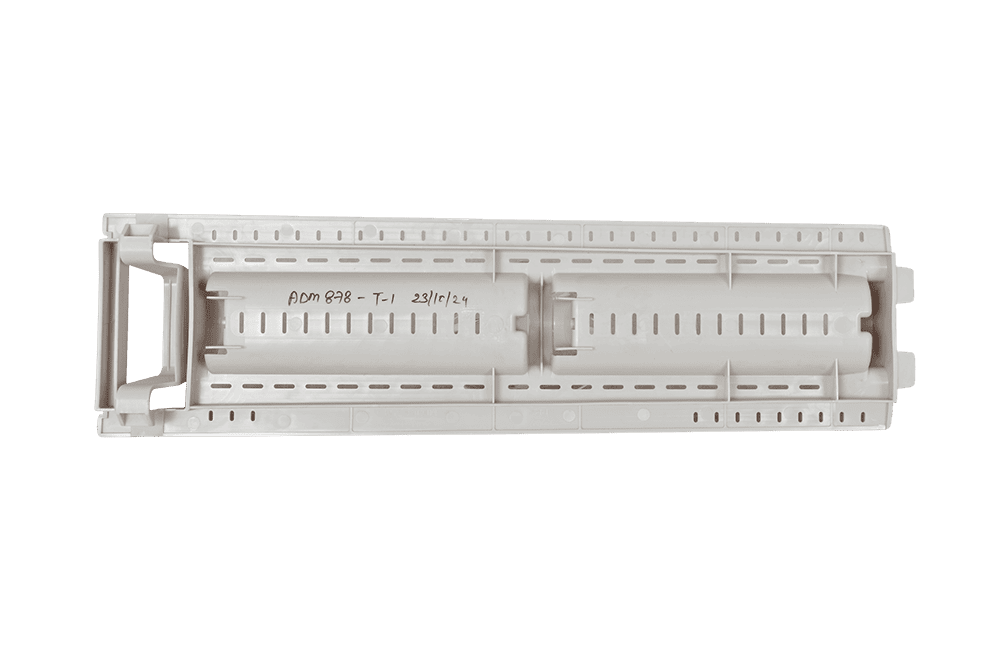

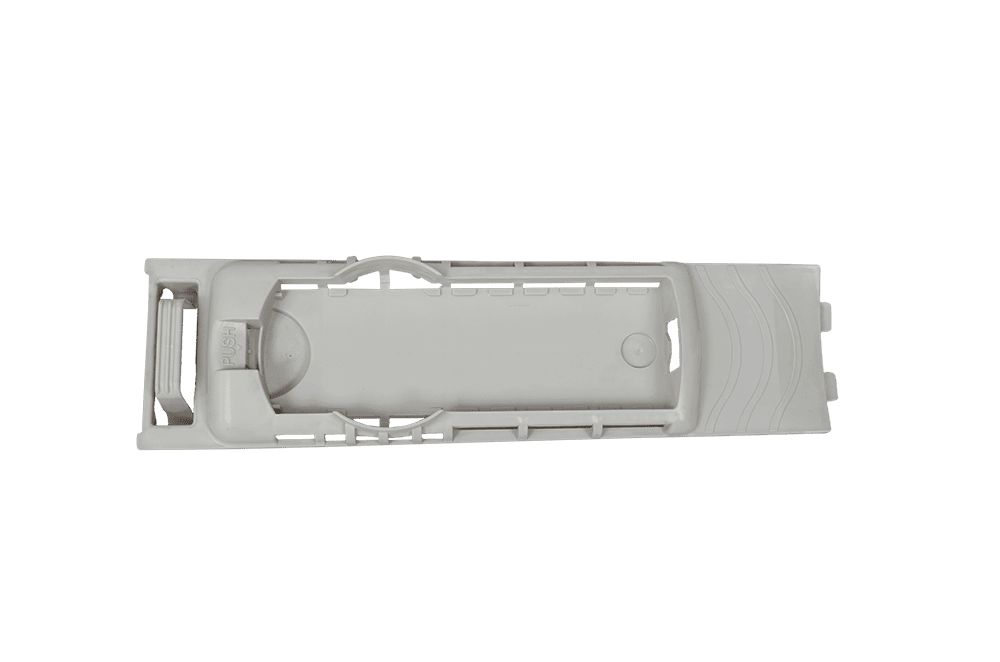

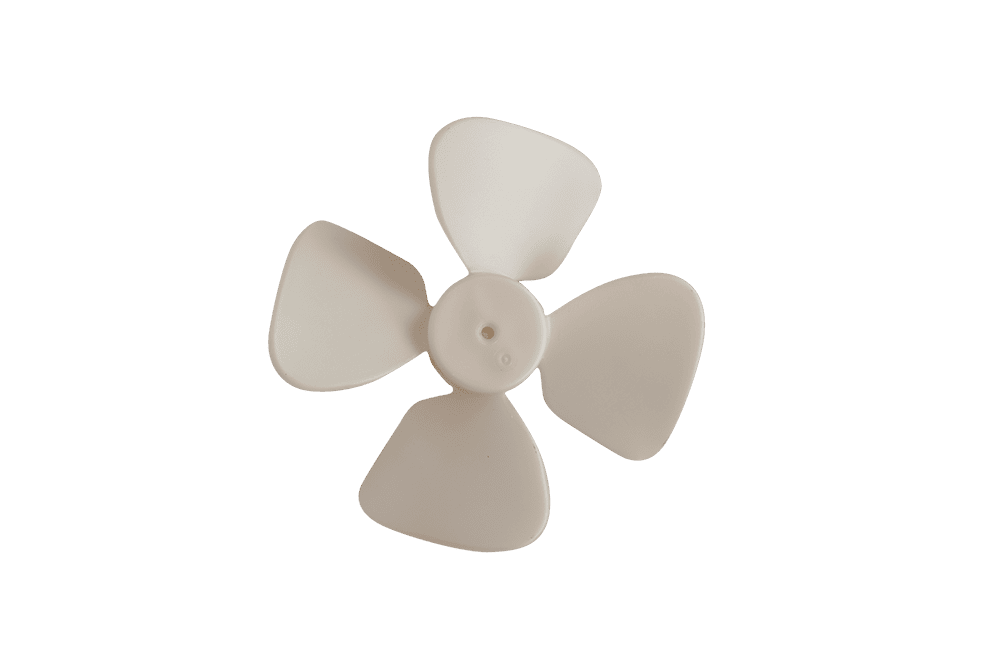

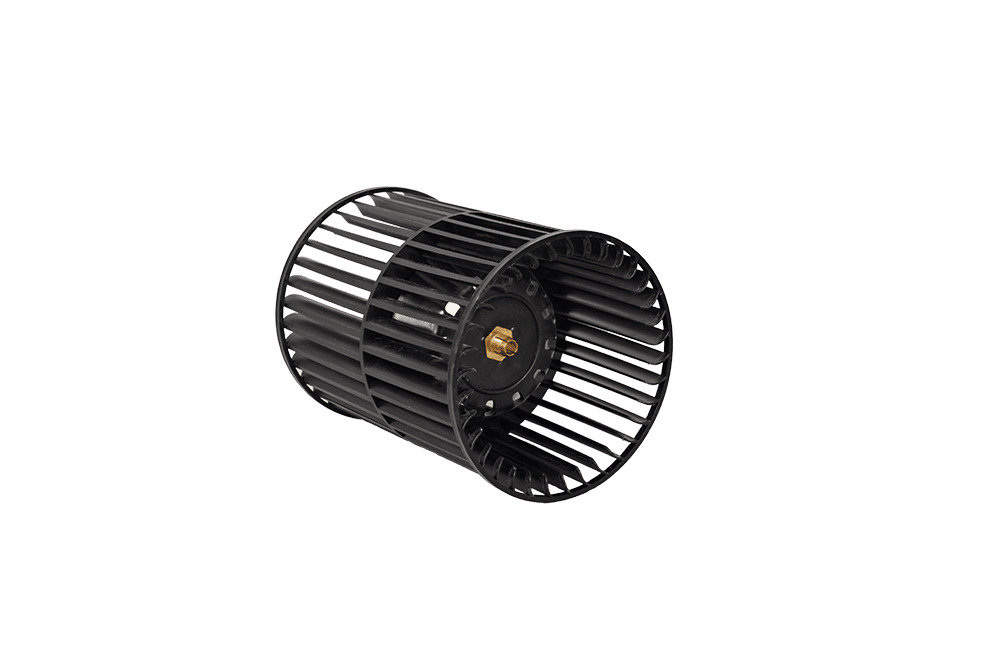

Home Appliances

Injection moulded parts are components made using the injection moulding process, which is a manufacturing method commonly used to produce plastic parts in high volumes. In this process, plastic material (usually in the form of pellets) is melted and injected into a metal mould cavity under high pressure. Once cooled, the plastic solidifies into the shape of the mould, and the part is ejected.

Some key points about injection moulded parts:

1. Precision: Injection moulding allows for high-precision parts with intricate designs and tight tolerances.

2. Materials: A wide variety of thermoplastics, thermosets, and elastomers can be used, depending on the application (e.g., ABS, polycarbonate, polypropylene).

3. Efficiency: It’s ideal for mass production, as the process is fast and highly repeatable.

4. Cost-effective: While the initial tooling (the mould) can be expensive, the per-unit cost drops significantly with larger production runs.

5. Applications: Used in industries like automotive, consumer electronics, medical devices, and packaging, just to name a few.